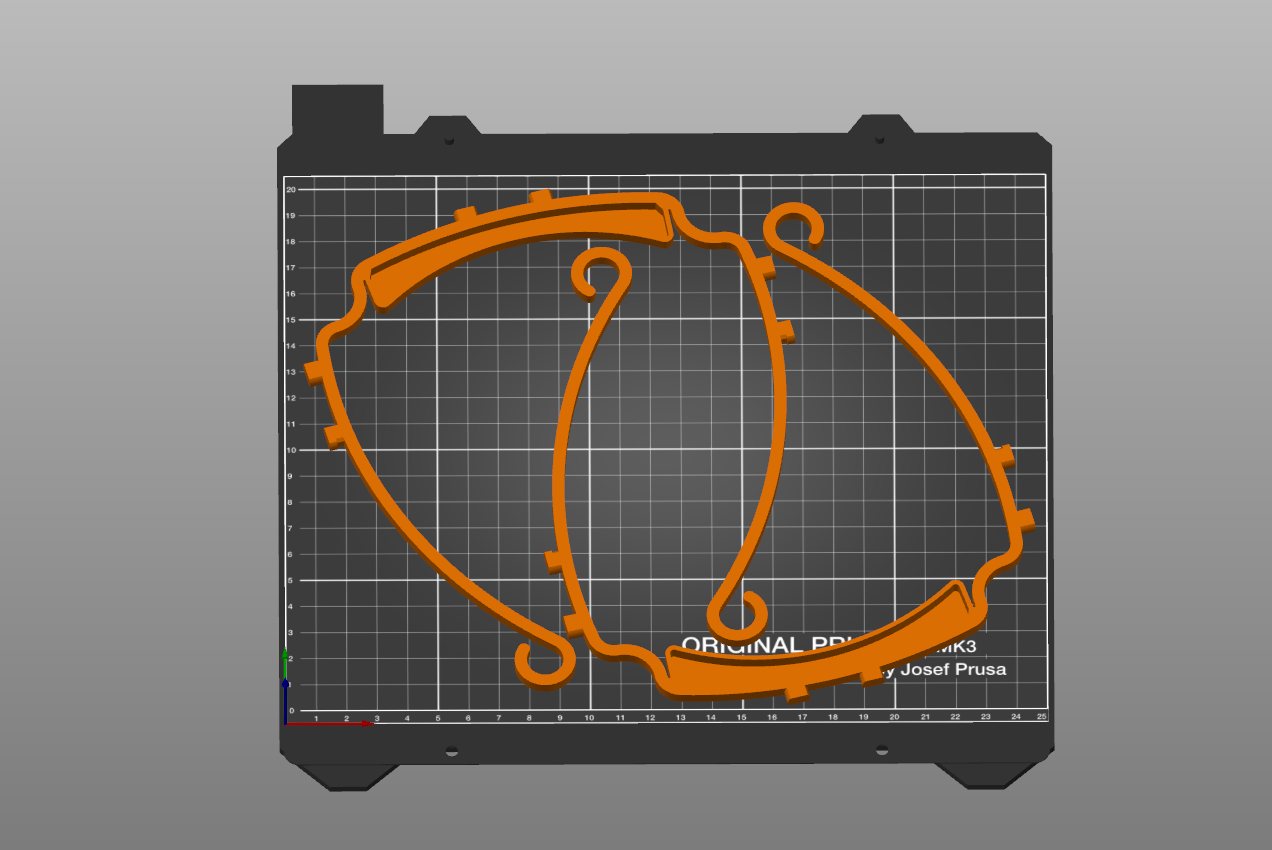

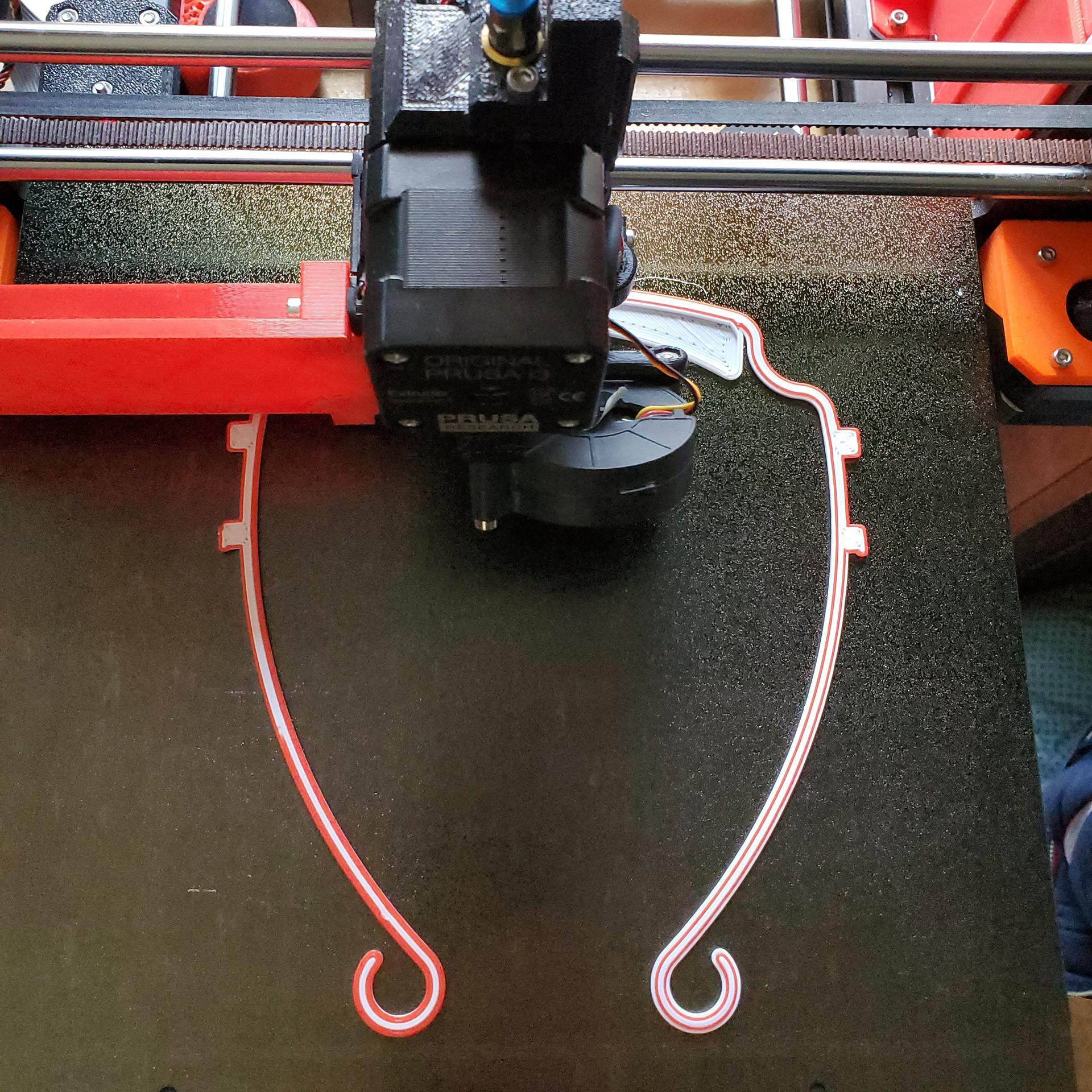

In late March of 2020, I learned about makers around the world who were using their 3D printers to print face shield frames, and I decided to start doing the same with my personal 3D printer, a Prusa i3 MK3s. The print bed had space for two frames, so I began printing two at a time, all the time. Every two took roughly 50 minutes to print (each face shield taking about 24 minutes), so they added up quickly. Through the Rotary club in my town, Bedford, MA, I was able to start distributing them to two local hospitals, UMass Medical Center and Lahey Medical Center. After a few weeks of nonstop printing, I wanted to automate the print process, so I designed a bumper to attach to the print head that could knock off a face shield from the print bed once it was finished to reduce the amount of time spent monitoring the printer. With the bumper installed, there was only room on the print bed for a single face shield to be bumped off at a time.

Once the bumper was in place, I added basic automation to the printer by editing the gcode for printing the face shields to include a cooling and removal procedure, as well as a multiplication of the print sequence to enable the 3D printer to print more face shields in one print. I capped the number of consecutive prints at ten to minimize the risk of a failure. (See below for a video of the operation)

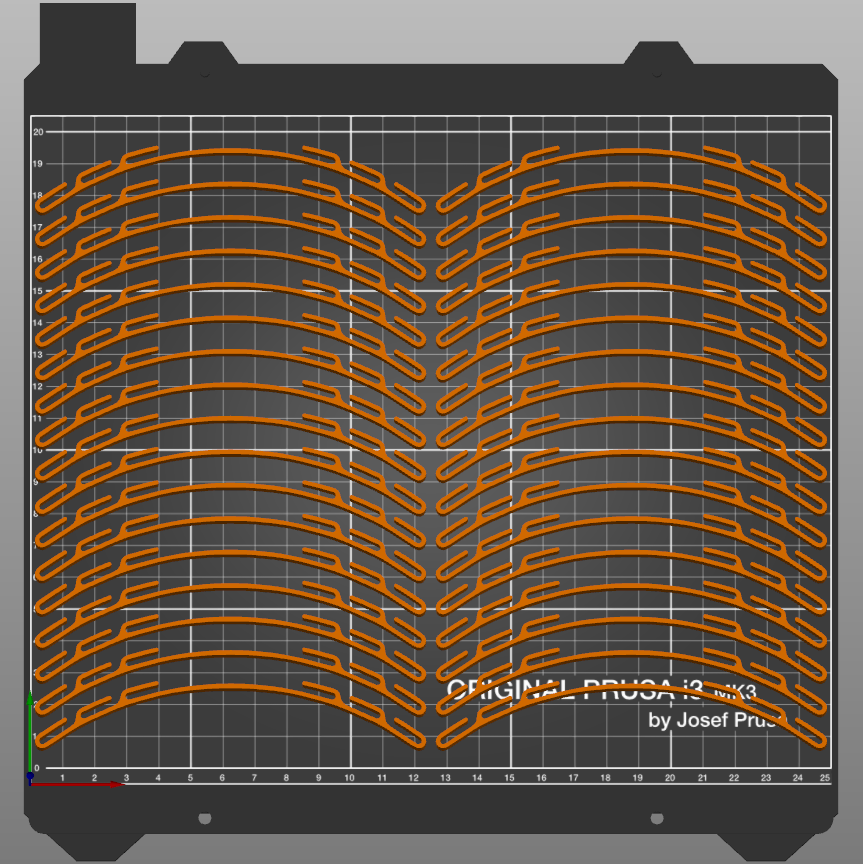

In June of 2020, I learned about "ear savers," which are small pieces designed to hold a mask from behind one's head to reduce the strain on the ears, particularly for healthcare workers who wear masks for extremely long periods of time. I found a design that worked with my bumper, and started printing some of them as well. I stopped after a few days due to the sheer volume that I printed; with 34 ear savers fitting on the print bed, just a night of printing yielded over 150!

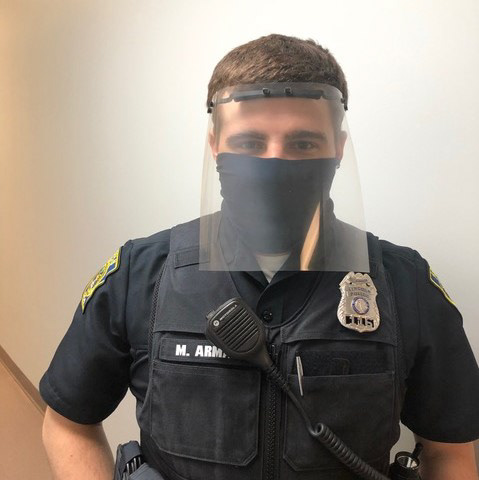

I stopped printing face shields in August 2020, right before starting my freshman year at WPI. In the end, I printed and assembled over 710 face shields, as well as an uncountable number of ear savers, that were delivered to and used by UMass Medical Center, Lahey Medical Center, fire and police departments in four local towns, two local nursing homes, and a COVID-19 testing center run by the Bedford Research Foundation.

Nurses at UMass MedicalCenter, one wearing a 3D printed face shield

Bedford Police Officer wearing a 3D printed face shield

Staff at the Bedford Research Foundation COVID-19 Testing Clinic wearing face shields

Videos of face shield frames being 3D printed: